GM Pioneers Adaptive Air Intakes: A Breakthrough in Vehicle Production Efficiency

General Motors (GM) has taken a significant step forward in automotive engineering by developing an innovative adaptive air intake duct. Recently unveiled through a 2022 patent application publication by the United States Patent and Trademark Office (USPTO) on June 27, 2024, this new technology aims to streamline vehicle manufacturing and boost cost-efficiency.

Adaptive Air Intake: A Game-Changer for GM

The adaptive air intake consists of a revolutionary setup featuring fixed inlet and outlet sections, complemented by a movable, flexible element in between. According to GM’s application, this middle section is crafted from a material capable of expanding and contracting in response to varying airflow volumes. Potential materials mentioned by GM include advanced polyethylene blends, waterproof felt, silicone fabric, and platinum-catalyzed silicon.

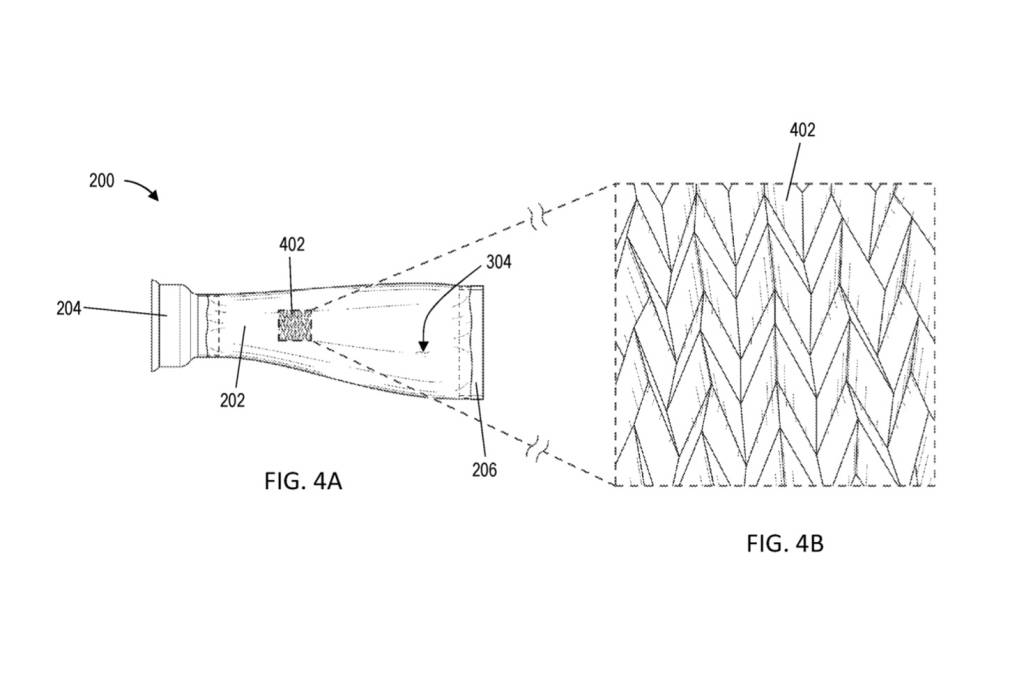

Patent image showcasing GM’s adaptive air intake

The Mechanics and Material Innovation

The principle behind the adaptive air intake is straightforward yet ingenious. With the capability to adjust its cross-sectional area based on airflow, this system can cater to a variety of vehicle needs without necessitating multiple design variations. GM emphasizes that this flexibility will significantly reduce manufacturing complexities and associated costs.

By employing materials like waterproof felt, silicone fabric, and advanced polyethylene blends, GM believes it can achieve the necessary flexibility and durability. These materials are designed to withstand the rigors of automotive environments while providing the adaptive functionality required.

Another patent image of GM’s adaptive air intake system

Efficiency and Cost Reduction

The introduction of an adaptive air intake system brings multiple advantages. Primarily, it ensures that a single air intake design can be utilized across various models, thereby reducing the need for distinct tooling and unique manufacturing processes for each vehicle type. This harmonization not only slashes production costs but also simplifies logistics and enhances space efficiency.

By enabling a unified approach to air intake design, GM is positioning itself to benefit from the cost-cutting advantages of parts commonality. The economic efficiency of such an approach cannot be overstated. Automakers typically aim to standardize high-cost components like engines and infotainment systems across their range, and now GM might extend this strategy to air intakes as well.

Conclusion

General Motors’ move towards an adaptive air intake system highlights the company’s commitment to innovation and efficiency. If successfully implemented, this technology could mark a significant advancement in reducing manufacturing complexities and costs while enhancing vehicle performance. Keep an eye on GM as they continue to push the boundaries of what’s possible in automotive engineering.

For the latest updates and insights on automotive innovations, visit our website Automotive.fyi, follow us on X at @automotivefyi, or send your news tips to tips@automotive.fyi.

Steven Hale, Editor of Automotive.fyi